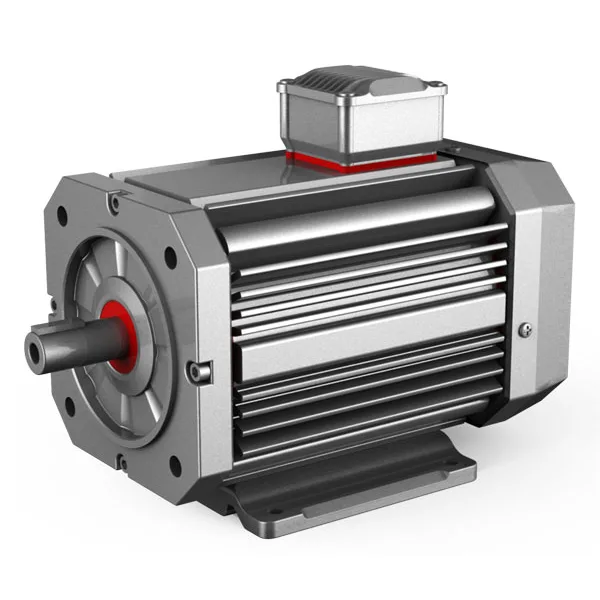

Product Specifications

| Brand Name: | Volcano Electric | Model Number: | IEC 1.5-100 | Type: | IEC Motors |

| Output Power: | 2 HP (1500W) | Voltage: | 180VDC, 230/460V/220/380 AC are available | Speed Range: | 1800 RPM |

| Controller: | Customized, Optional | Braker: | Optional | Insulation Class: | Class F/H |

| Enclosure: | IP44 / IP54 / IP56, IP65, IP66, IPW56, IPW65 or IPW66 | Poles: | 2P, 4P, 6P, 8P… | Wire: | 100% copper |

| Housing: | Aluminum Frame | Efficiency: | IE2, IE3 or IE4 efficiency classes | Material: | Neodymium Magnets |

| Duty: | S1 (continuous) | Place of Origin: | Zhejiang, China (Mainland) | Standard: | IEC / NEMA standard |

| Application: | Compressors, Conveyor, Blowers, Fans, Irrigation, Pumps, Heat Exchangers, Cranes & Hoist, Printing, Extruders etc | ||||

Product Description

Four key features of Volcano Electric IEC motors include their efficiency, reliability, use of cutting-edge technology, and virtually unlimited customization options.

The copper content in the windings determines the motor’s power requirements. Striking the right balance is crucial to creating a motor that maximizes torque without requiring enormous power. The magnetic flux path guides all magnetic field within the available channels, minimizing losses. A motor that produces high power but has high losses is detrimental to the application. Understanding the complete motor design enables Volcano Electric engineers to pack as much power as possible into the smallest possible motor package.

Volcano Electric designs brushless DC motors to maximize torque output while minimizing diameter and length. High-energy neodymium magnets provide the foundation for the torque density of this series of motors. High-capacity windings increase current density and electromagnetic intensity, minimizing Joule heating. The advanced airgap design requires less power to achieve high torque output, enabling the motor to operate at high efficiency.

SOME OF Metric IEC MOTORS

| Power KW/HP |

Speed RPM |

Voltage* DC |

Load Amps |

IEC Frame |

| 0.25/1/3 | 1800 | 180 | 1.7 | 71 |

| 0.7/1/2 | 3000 | 180 | 2.5 | 71 |

| 0.7/1/2 | 1800 | 180 | 2.5 | 71 |

| 0.55/3/4 | 3000 | 180 | 3.6 | 71 |

| 0.55/3/4 | 1800 | 180 | 3.5 | 80 |

| 0.75/1 | 3000 | 180 | 4.9 | 80 |

| 0.75/1 | 1800 | 180 | 4.6 | 80 |

| 1.1/1.5 | 3000 | 180 | 7.1 | 80 |

| 1.1/1.5 | 1800 | 180 | 7 | 80 |

| 1.1/1.5 | 1800 | 180 | 7.5 | 90L |

| 1.5/2 | 3000 | 180 | 10 | 90L |

| 1.5/2 | 1800 | 180 | 9.5 | 90L |

| 2.2/3 | 3000 | 180 | 16 | 90L |

| 2.2/3 | 1800 | 180 | 14 | 112M |

Voltage* :These IEC motors are also available for AC condition, please notify your voltage availabe in advance

IEC MOTOR FRAME SPECIFICATIONS

| IEC MOTOR FRAME SPECIFICATIONS | |||||

| Frame | Rated Power | H | A | B | L |

| 71 | 370w-1.5kw | 71 | 112 | 90 | 250-270 |

| 80 | 370W-2.2KW | 80 | 125 | 100 | 275-300 |

| 90 | 370W-3KW | 90 | 140 | 125 | 335-350 |

| 100 | 370W-4.5KW | 100 | 160 | 140 | 365-400 |

| 112 | 370W-5.5KW | 112 | 190 | 140 | 395-420 |

NEMA MOTOR FRAME SPECIFICATIONS

| NEMA MOTOR FRAME SPECIFICATIONS | |||||

| Frame | Rated Power | H | A | B | L |

| 143T | 370w-1.5kw | 3.5 | 2.7 | 2 | 12.5 |

| 145T | 370W-2.2KW | 3.5 | 2.7 | 2.5 | 13.5 |

| 182T | 370W-3KW | 4.5 | 3.7 | 2.25 | 15.3 |

| 184T | 370W-4.5KW | 4.5 | 3.7 | 2.75 | 16 |

| 213T | 370W-5.5KW | 5.25 | 4.2 | 2.75 | 19 |

Customized Motors

Besides of the standard IEC Motors, Volcano Electric can offer customized motor and supplier comprehensive solutions of your whole system, please contact our technician, Ordinary, we have to know the following information to get a professional proposal:

- Brushed or Brushless: Customer preference

- Output power (W): Horsepower/watts/torque rated at full load speed

- Voltage (V): i.e 12V DC …….. 450V AC

- Motor speed (RPM): Revolutions per minute of the shaft at full load Voltage

- Application: e.g. traction, air condition, etc.

- Duty: Most motors are rated continuous. Some applications however may use motors designed for intermittent duty

- Configuration/Frame: Our products are according to IEC standard, we also can customize the flange and shaft according to the customer drawing

- Controller function: e.g. forward/reverse, variable speed, acceleration profile, etc.