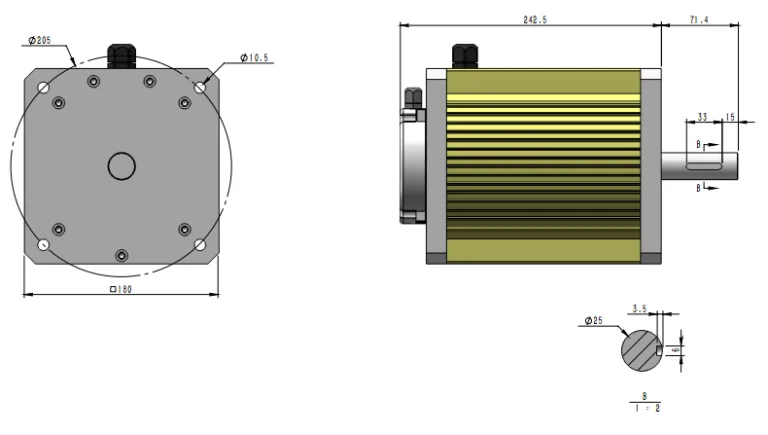

Product Specifications

| Brand Name: | Volcano Electric | Model Number: | VOL-BL100A110 | Type: | Brushless DC Motor |

| Output Power: | 1000W | DC Voltage: | 110V | Speed Range: | 1500 RPM |

| Current: | 5.71A | Torque: | 6.37Nm | Sensor: | Hall sensor |

| Controller: | Customized, Optional | Braker: | Optional | Insulation Class: | Class F |

| Enclosure: | IP54, IP55 | Poles: | 8P | Wire: | 100% Copper |

| Housing: | Aluminum | Efficiency: | up to 92% | Certification: | CE, UL |

| Duty: | S1 | Place of Origin: | Zhejiang, China (Mainland) | Standard: | IEC / Custom |

| Application: | Boat, Electric Vehicle, Scooter, Sightseeing cars, Home Appliance, Pump, bus A/C systems ,Other | ||||

Any one of the below requirements, you have to choose a reasonable permanent magnet motors.

- Variable speed application

- Require High Start Torque

- Low /High speed application

- Minimize Motor size demands

- Customized Speed, work at any defined speed, ( the rated speed of AC motor is limited, 2 poles-3000RPM, 4 poles -1500RPM @50HZ, 2 poles-3600RPM, 4 poles -1800RPM @60HZ)

- Battery driven required

Product Description

This customized 4kW, 2580RPM permanent magnet motor is designed for electric vehicles. Combined with our specialized motor drive, it also enables electric vehicles to operate at high efficiency. It’s crucial that the motor and drive are compatible to maximize overall system efficiency.

With 30 years of experience in motor manufacturing and 10 years of experience in motor drive R&D, we can provide customers with comprehensive motor and controller solutions for a variety of applications.

If you have any specific requirements for your motor, please feel free to contact our engineers at infor@volcanomotors.com.

How are BLDC motors controlled?

An electronic BLDC controller (also known as a drive or electronic speed controller) replaces the mechanical commutation system used in brushless DC motors and is required for most brushless DC motors. In brushless DC motor controllers, Hall effect sensors or back-electromotive force (BEMF) are used to identify the rotor’s position. Knowing the rotor’s direction is crucial for operating a BLDC motor.

Configuration

Brushless motor list

| Motor type | Output | Voltage | Load | Speed | Rated Torque | Poles | Efficiency | Noise |

| KW | V | A | RPM | N.m | % | dB | ||

| BLDC1.55-154 | 1.55 | 45 | 40 | 4300 | 3.44 | 8 | 86 | 60 |

| BLDC1.8-154 | 1.8 | 60 | 32.6 | 1100 | 15.6 | 8 | 92 | 61 |

| BLDC1.85-154 | 1.85 | 24 | 81.5 | 2100 | 8.41 | 8 | 92 | 60 |

| BLDC2.7-154 | 2.7 | 60 | 48.9 | 1100 | 23.4 | 8 | 92 | 61.5 |

| BLDC2.8-154 | 2.8 | 60 | 50.8 | 1100 | 24.3 | 8 | 92 | 61.5 |

| BLDC2.8-154 | 2.8 | 48 | 67.8 | 2600 | 10.3 | 8 | 86 | 61 |

| BLDC3.0-154 | 3.0 | 48 | 67.6 | 2650 | 10.81 | 8 | 92.5 | 61 |

| BLDC3.0B-154 | 3.0 | 72 | 46.8 | 1850 | 15.5 | 8 | 89 | 61 |

| BLDC3.5B-154 | 3.5 | 60 | 69.5 | 1680 | 19.9 | 8 | 84 | 61 |

| BLDC4.0-154 | 4.0 | 48 | 90.6 | 2580 | 14.81 | 8 | 92 | 62 |

| BLDC5.5-154 | 5.5 | 72 | 85.6 | 3680 | 14.27 | 8 | 89.2 | 63 |

Advantages of Brushless DC motors

- Lower maintenance and longer lifetime- no brush and commutator erosion

- Lower noise-the elimination of brush contact

- Higher power to weight ratio

- Higher efficiency ( in general higher than 90%)

- Lower temperature rise-more efficient heat dissipation due to winding construction

- Reduction of EMI

Customized Motors

For customized Motors, please contact our technician, Ordinary, we have to know the following information to get a professional proposal:

- Brushed or Brushless: Customer preference

- Output power (W): Horsepower/watts/torque rated at full load speed

- Voltage (V): i.e 12V DC …….. 450V AC

- Motor speed (RPM): Revolutions per minute of the shaft at full load Voltage

- Application: e.g. traction, air condition, etc.

- Duty: Most motors are rated continuous. Some applications however may use motors designed for intermittent duty

- Configuration/Frame: Our products are according to IEC standard, we also can customize the flange and shaft according to the customer drawing

- Controller function: e.g. forward/reverse, variable speed, acceleration profile, etc.