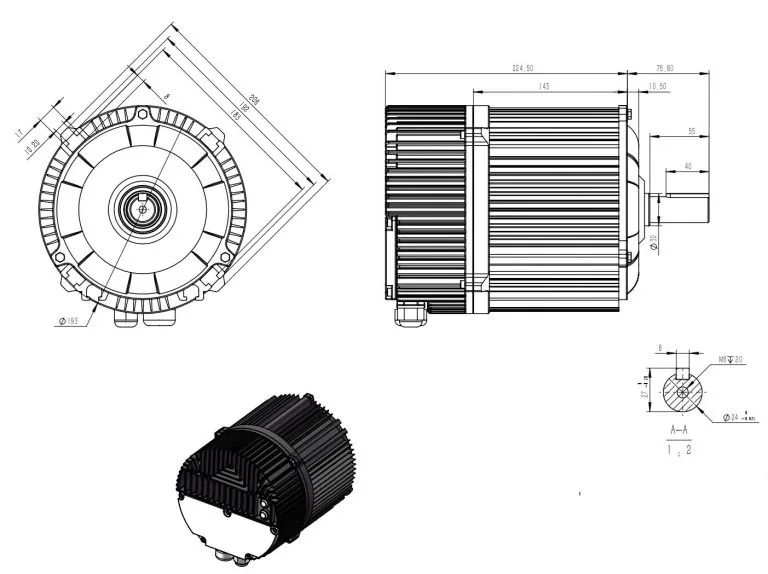

Product Specifications

| Brand Name: | Volcano Electric | Model Number: | HSE-PM38H075-160N06-S4X | Type: | Brushless DC motor |

| Output Power: | 600W | DC Voltage: | 380VAC | Speed Range: | 600 RPM |

| Control Mode | Potentiometer or RS485/Mobus | Braker: | Optional | Insulation Class: | Class F |

| Enclosure: | IP67 | Poles: | 10P | Wire: | 100% copper |

| Housing: | Aluminum | Efficiency: | IE 5.0 | ||

| Duty: | S1 | Place of Origin: | Zhejiang, China (Mainland) | Standard: | IEC standard |

| Application: | Data Center Cooling,HVAC(Heating, Ventilation, and Air Conditioning), Medical Ventilation Systems, Livestock Farming Environments | ||||

Product Description

EC fans (Electronically Commutated Fans) are innovative ventilation devices that combine electronic control technology with brushless motor technology. Leveraging advantages such as high energy efficiency, intelligent controllability, and strong durability, they have widely replaced traditional AC fans and become a core ventilation solution in industries including industrial manufacturing, commercial services, and agriculture.

EC fans receive external signals (e.g., temperature, humidity, 0-10V analog signals) via an ECU (Electronic Control Unit). This ECU regulates the direction of current in the motor’s stator windings, driving the permanent magnet rotor to rotate—all without mechanical contact. The result is operation characterized by “no wear, low noise, and variable speed.”

Compared to traditional AC fans (especially fixed-speed AC fans), EC fans offer significant performance improvements:

- Motor Efficiency: EC fan motors achieve 85%-95% efficiency (vs. only 50%-70% for AC fans), with some models meeting the highest IE5 energy efficiency standard.

- Energy Savings: During variable-speed operation, energy consumption decreases linearly with air volume demand, cutting electricity use by 30%-60% compared to fixed-speed AC fans.

- Intelligent Connectivity: They support 0-10V analog control and RS485/MODBUS digital communication, enabling integration with PLC systems and IoT platforms.

- Longer Lifespan & Durability: Without brush wear, permanent magnet EC motors last 50,000-100,000 hours (vs. 15,000-30,000 hours for AC fans). With IP54-IP67 protection ratings, they resist dust, moisture, and corrosive gases (such as ammonia in livestock farms).

Photovoltaic

Volcano Electric EC fan motor can be combined with the photovoltaic unit and storage battery through a unique High-voltage solar energizer which makes solar energy,battery power and grid power complement each other to supply power to multiple motors 24/7.These solution form a high-efficiency conversion unit to optimize solar energy utilization and reduce electricity costs significantly.

Waiting for you and feel free to contact our team at info@volcanomotors.com for any technical support.

Configuration

EC Inner Rotor motor HSE160 list

| Model Definition | Rated Voltage(VAC) | Rated Power(kW) | Rated Speed(RPM) | Rated Torque(Nm) | Cettification | Remote Communication Protocal | Protection Level |

| HSE-PM38H075-160N06-S4X | 380 | 0.75 | 600 | 12 | Suit EMC | MODBUS | IP67 |

| HSE-PM38H075-160N08-S4X | 380 | 0.75 | 850 | 8.5 | Suit EMC | MODBUS | IP67 |

| HSE-PM38H110-160N07-S4X | 380 | 1.1 | 700 | 15 | Suit EMC | MODBUS | IP67 |

| HSE-PM38H110-160N15-S4X | 380 | 1.1 | 1500 | 7 | Suit EMC | MODBUS | IP67 |

| HSE-PM38H150-160N05-S4X | 380 | 1.5 | 580 | 25 | Suit EMC | MODBUS | IP67 |

| HSE-PM38H150-160N06-S4X | 380 | 1.5 | 650 | 22 | Suit EMC | MODBUS | IP67 |

| HSE-PM38H150-160N07-S4X | 380 | 1.5 | 700 | 20 | Suit EMC | MODBUS | IP67 |

| HSE-PM38H150-160N09-S4X | 380 | 1.5 | 960 | 15 | Suit EMC | MODBUS | IP67 |

| HSE-PM38H150-160N15-S4X | 380 | 1.5 | 1500 | 10 | Suit EMC | MODBUS | IP67 |

| HSE-PM38H220-160N07-S4X | 380 | 2.2 | 750 | 28 | Suit EMC | MODBUS | IP67 |

| HSE-PM38H220-160N11-S4X | 380 | 2.2 | 1100 | 19 | Suit EMC | MODBUS | IP67 |

| HSE-PM38H220-160N14-S4X | 380 | 2.2 | 1400 | 14 | Suit EMC | MODBUS | IP67 |

| HSE-PM38H350-160N11-S4X | 380 | 3.5 | 1150 | 30 | Suit EMC | MODBUS | IP67 |

| HSE-PM38H350-160N15-S4X | 380 | 3.5 | 1500 | 22 | Suit EMC | MODBUS | IP67 |

| HSE-PM22H075-160N04-S4X | 220 | 0.75 | 460 | 15.5 | Suit EMC | MODBUS | IP67 |

| HSE-PM22H085-160N05-S4X | 220 | 0.85 | 560 | 14.5 | Suit EMC | MODBUS | IP67 |

| HSE-PM22H150-160N15-S4X | 220 | 1.5 | 1500 | 14 | Suit EMC | MODBUS | IP67 |

| HSE-PM22H220-160N15-S4X | 220 | 2.2 | 1500 | 21 | Suit EMC | MODBUS | IP67 |

Advantages of EC Inner Rotor motors

- High Efficiency&Energy Saving:Meets IE5 energy efficiency standrds.

- Speed Control:Integrated 0-10V speed regulation and RS485-MODBUS remote control technology.

- Integrated Design: Front motor and rear drive for compact,efficient systems.

- Wide Voltage Range:Support 380VAC±20% voltage tolerance.

- Motor Protection: Ober-voltage, under-voltage,over-current.and phase loss protection

- Electromagnetic Compatibility:Complies with EMC standards, minimizing interference.

Customized Motors

For customized Motors, please contact our technician, Ordinary, we have to know the following information to get a professional proposal:

- Brushed or Brushless: Customer preference

- Output power (W): Horsepower/watts/torque rated at full load speed

- Voltage (V): i.e 12V DC …….. 450V AC

- Motor speed (RPM): Revolutions per minute of the shaft at full load Voltage

- Application: e.g. traction, air condition, etc.

- Duty: Most motors are rated continuous. Some applications however may use motors designed for intermittent duty

- Configuration/Frame: Our products are according to IEC standard, we also can customize the flange and shaft according to the customer drawing

- Controller function: e.g. forward/reverse, variable speed, acceleration profile, etc.