Product Specifications

| Brand Name: | Volcano Electric | Model Number: | BLDC0.157-47 | Type: | PMSM Motors |

| Output Power: | 50W-160W | Voltage: | 70V DC | Speed Range: | 5000 RPM |

| Controller: | Customized, Optional | Braker: | Optional | Insulation Class: | Class B/F/H |

| Enclosure: | IP44 / IP54 | Poles: | 4P, 6P, 8P… | Wire: | 100% copper |

| Housing: | Aluminum Frames/ cast iron frames | Efficiency: | High efficiency | ||

| Duty: | S1 (continuous) | Place of Origin: | Zhejiang, China (Mainland) | Standard: | OEM, customized PMSM motors |

| Application: | Textile machinery, packing machine, automatic conveyor belt etc. | ||||

Any one of the below requirements, you have to choose a reasonable permanent magnet motors.

- Variable speed application

- Require High Start Torque

- Low /High speed application

- Minimize Motor size demands

- Customized Speed, work at any defined speed, ( the rated speed of AC motor is limited, 2 poles-3000RPM, 4 poles -1500RPM @50HZ, 2 poles-3600RPM, 4 poles -1800RPM @60HZ)

- Battery driven required

Product Description

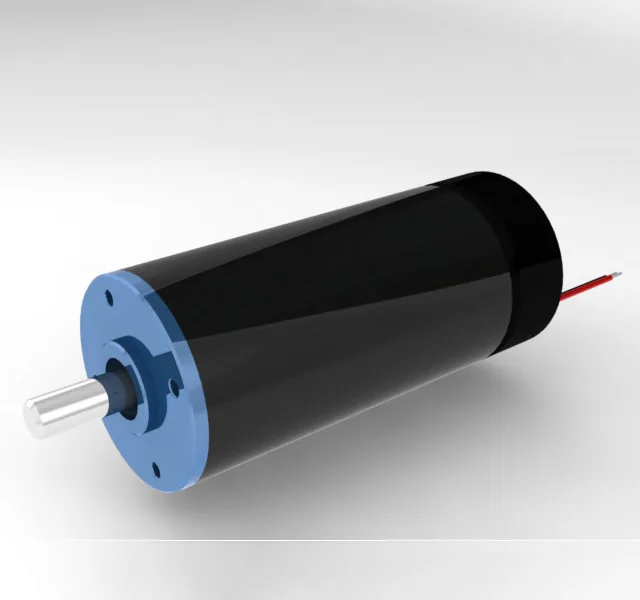

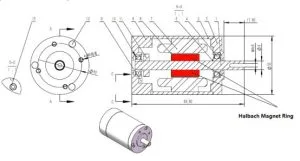

PMSM motor structure as following:

The rotor is made by sintered neodymium Magnet halbach ring, the magnetic force is almost 3 times of bond magnet rotor. The magnetic density is stronger, and it can reduce the coils of stator.

This PMSM motor’s benefits:

- Minimized Motor size. (Smaller than conventional motors)

- Start faster

- Minimize the copper loss

- Higher efficiency

This customized PMSM Motor is designed to apply to servo applications, with low cogging torque; it can be used in the applications which use brushless DC motors. what’s more, High precision servo application can be realized with the encoder.

This customized PMSM Motor size is small, the diameter is D52mm and the length 100mm adjustable, and it depends on the motor power.

This customized PMSM Motor is used in bobbin winder automatic system; this motor is replacing the conventional electric motors. The efficiency of the PMSM motors are increased almost 8%-15%. And because of 10 poles systems, the motor starting is much faster on the line. We designed three various PMSM motors by customers demands. For more specifications on this leading motors, please contact our technical team by email info@volcanomotors.com

Basic Parameter of the quantum series PMSM motors

| Motor Model | PMSM-42 | PMSM-52 | PMSM-62 |

| Supply Voltage-Un | 12V,24V,36V,48V,60V,72V,110V,220V,380V | ||

| Insulation Voltage | 8xUn, during time>3 Sec | ||

| Insulation Class | F | ||

| Efficiency | 90% | 90% | 92% |

| Speed | 3000~12000RPM | ||

| Running Torque | 0.03~0.26NM | 0.05~0.3NM | 0.15~0.3NM |

| Power Output | 30~80W | 50~180W | 150~350W |

| IP Standard | IP44 (IP 68 Optional) | ||

| Life Expectancy | 3 Years continous Pperation | ||

| Ambient Temperature | -15℃~40℃ Continous Operation | ||

Advantages of Brushless DC motors

- Lower maintenance and longer lifetime- no brush and commutator erosion

- Lower noise-the elimination of brush contact

- Higher power to weight ratio

- Higher efficiency ( in general higher than 90%)

- Lower temperature rise-more efficient heat dissipation due to winding construction

- Reduction of EMI

Customized Motors

For customized Motors, please contact our technician, Ordinary, we have to know the following information to get a professional proposal:

- Brushed or Brushless: Customer preference

- Output power (W): Horsepower/watts/torque rated at full load speed

- Voltage (V): i.e 12V DC …….. 450V AC

- Motor speed (RPM): Revolutions per minute of the shaft at full load Voltage

- Application: e.g. traction, air condition, etc.

- Duty: Most motors are rated continuous. Some applications however may use motors designed for intermittent duty

- Configuration/Frame: Our products are according to IEC standard, we also can customize the flange and shaft according to the customer drawing

- Controller function: e.g. forward/reverse, variable speed, acceleration profile, etc.