Product Specifications

| Brand Name: | Volcano Electric | Model Number: | VOL-WSRS60 9S | Type: | Brushless DC Motor |

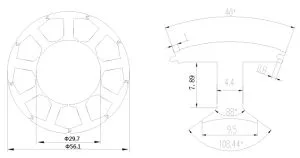

| OD of Stator: | 56.1mm | ID of Stator: | 29.7mm | Tooth width: | 6mm |

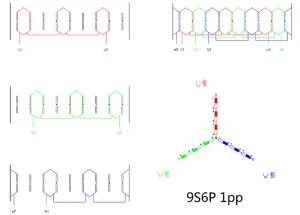

| Number of slots: | 9 | Poles: | 6 poles | Multi strands: | 1pp, 3pp |

| Power: | 150W~600W | Speed: | 500~6000RPM | Wire: | 100% Copper Coil |

| Insulation Class: | Class F | Certification: | CE, UL, ROHS | Standard: | IEC or Custom |

| Application: | servo motor, robotics, electrical vehicle, brushless dc motor, industrial zone, pump | ||||

Product Description

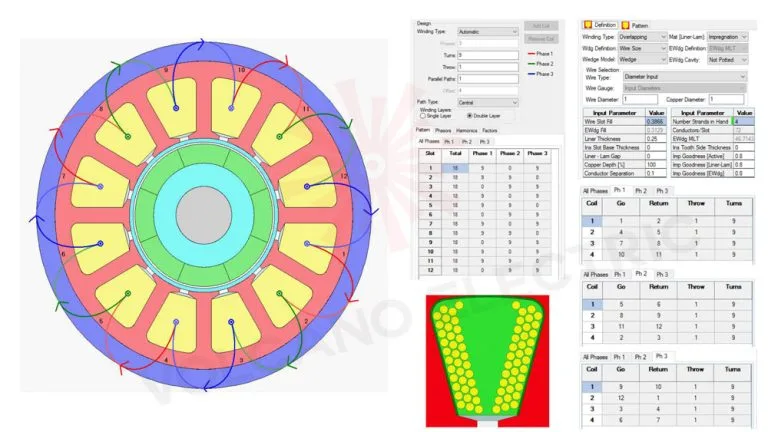

The VOL-WSRS60 9S, all permanent magnets are manufactured in our own factory. SPM and IPM rotors and components ensure that they meet the needs of different applications. The stator is designed with a single-tooth die and the copper wire is wound with automatic winding equipment, so when the motor is mass-produced, it can be produced very quickly. It is designed for large quantities.

Feel free to contact our team at info@volcanomotors.com for any technical support.

Multi Strands Showing

Motor construction

Brushless dc motor also have the stator and rotor same like the common dc motor, but it cancel the brushes. The stator used by silicon steel sheet and the rotor make by permanent magnet. It can be 2 poles to 8 poles just as you wish. Different with the brushes dc motor, the commutation of the BLDC motor is electronically controlled. We will use the hall sensors to do it. Also can use the magnetic encoder.

Specifications

| Model Number | WSRS60 9S |

| Outer diameter of stator | 56.1mm |

| Inner diameter of stator | 29.7mm |

| Tooth width | 6mm |

| Number of slots | 9 |

| Poles | 6 poles |

| Multi-strands | 1pp or 3pp |

| Power | 150W ~ 600W |

| Speed | 500 ~ 6000RPM |

Detailed Images

Winding stator and rotor list

| Type | Outer diameter of stator | Inner diameter of stator | Tooth width | Number of slots | Poles | Multi-strands | Power | Speed |

| mm | mm | mm | pp | w | rpm | |||

| VOL-WSRS120 | 119 | 80 | 10 | 12 | 8 or 10 | 1 or 2 or 4 | 375-2000 | 500-5000 |

| VOL-WSRS250 | 215.2 | 136.2 | 16 | 18 | 12 or 24 or 36 | 1 or 2 or 6 | 2000-60000 | 500-5000 |

| VOL-WSRS220 | 200 | 120.1 | 19 | 12 | 8 or 10 | 1 or 2 or 4 | 2000-30000 | 500-5000 |

| VOL-WSRS180 | 167.2 | 110 | 15 | 12 | 8 or 10 | 1 or 2 or 4 | 1000-15000 | 500-5000 |

| VOL-WSRS130 M | 122 | 80 | 12.5 | 12 | 8 or 10 | 1 or 2 or 4 | 375-3000 | 500-5000 |

| VOL-WSRS130 S | 122 | 80 | 11.5 | 12 | 8 or 10 | 1 or 2 or 4 | 375-3000 | 500-5000 |

| VOL-WSRS100 | 90 | 44.6 | 6.5 | 12 | 8 or 10 | 1 or 2 or 4 | 375-2000 | 500-6000 |

| VOL-WSRS80 9S | 76.4 | 44.6 | 7.2 | 9 | 6 | 1 or 3 | 200-1000 | 500-6000 |

| VOL-WSRS80 12S | 77 | 40.5 | 7.2 | 12 | 8 or 10 | 1 or 2 or 4 | 200-1000 | 500-5000 |

| VOL-WSRS-60 9S | 56.1 | 29.7 | 6 | 9 | 6 | 1 or 3 | 150-600 | 500-6000 |

| VOL-WSRS-60 12S | 57.8 | 30.5 | 5.5 | 12 | 8 or 10 | 1 or 2 or 4 | 150-600 | 500-5000 |

Advantages of Brushed DC motors

- Reduce eddy current

- Lower noise

- Cools the stator core

- Reduces hysteresis loss

- Higher coil filling achievable. We can control 90% for High voltage, while 80% for low voltage

- Various stamping tools available to save initial design

- Large material savings compared to one piece stator

- Various grade of magnet

- Better magnetic properties, low demagnetization rate, and high magnetic consistence

- Multi-poles ring magnet: more stable & stronger magnetic flux to lower motor space and improve performance and lower spacer

Designed experiences for winding stator and rotor

For customized DC Motors, please contact our technician. Ordinary, we have to know the following information to get a professional proposal:

- Brushed or Brushless Customer preference

- Output power (W) Horsepower/watts/torque rated at full load speed

- Voltage (V) i.e 12v DC …….. 220v AC

- Motor speed (RPM) Revolutions per minute of the shaft at full load Voltage

- Application e.g. traction, airconditioning, etc.

- Duty Most motors are rated continuous. Some applications however may use motors designed for intermittent duty

- Configuration/Frame Our products are according to IEC standard, we also can customize the flange and shaft according to the customer drawing

- Controller function e.g. forward/reverse, variable speed, acceleration profile, etc.