Product Specifications

| Brand Name: | Volcano Electric | Model Number: | DC0.375/48-126 | Type: | Brushed DC motor |

| Output Power: | 1/2 HP ( 375W ) | DC Voltage: | 48V | Speed Range: | 1500 RPM |

| Controller: | Customized, Optional | Braker: | Optional | Insulation Class: | Class B/F/H |

| Enclosure: | IP44 / IP54 | Poles: | 4P, 6P, 8P… | Wire: | 100% copper |

| Housing: | Aluminum | Efficiency: | IE 4.0 | Fan: | Optional |

| Duty: | S1 (continuous) | Place of Origin: | Zhejiang, China (Mainland) | Standard: | IEC standard or NEMA standard |

| Application: | Boat, Car, Electric Bicycle, Fan, Home Appliance, Traction Motor, Solar Pump DC systems, bus A/C systems , other | ||||

Product Description

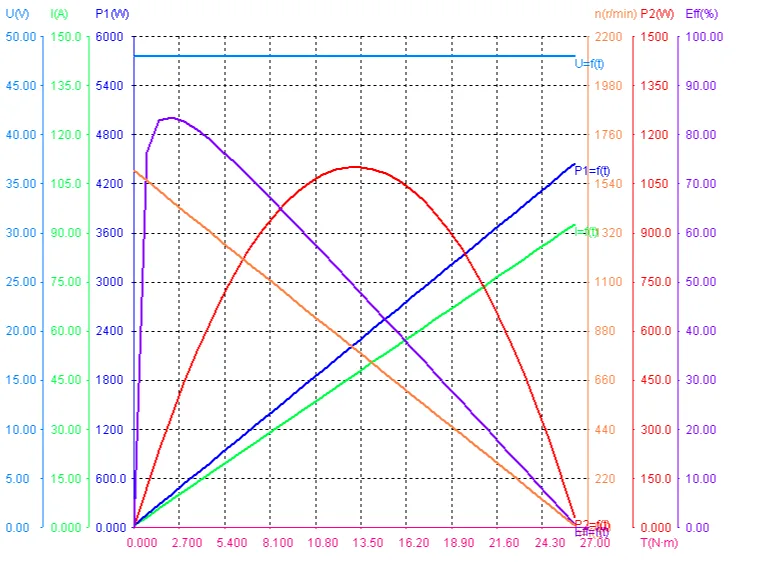

DC0.375/48-126 the rated speed is 1500RPM, the rated voltage is 48vdc, the rated power is 375w. The advantage of DC motor in comparison to AC motor is the wide speed range. The brushed DC motor can keeps at high efficiency at wide speed range, but for AC motor, the efficiency would get down a lot out of rated speed.

375W which means 1/2HP motors are popular used in various application. The customer can have various options, AC induction motor, brushed DC motors, Brushless DC motors. Which motor is best fitted yours, please do contact our engineer for further advices by your case.

Brushed Motor Advantages:

Simplified wiring: Brushed motors can be wired directly to DC power and control can be a simple as a switch.

Low cost

Brushed Motor Disadvantages:

Less efficient

Electrically noisy: The switching action of the commutators constantly creating and breaking inductive circuits creates a great deal of electrical and electromagnetic noise.

Lifespan: As they are in perpetual physical contact with the shaft, brushes and commutators wear out.

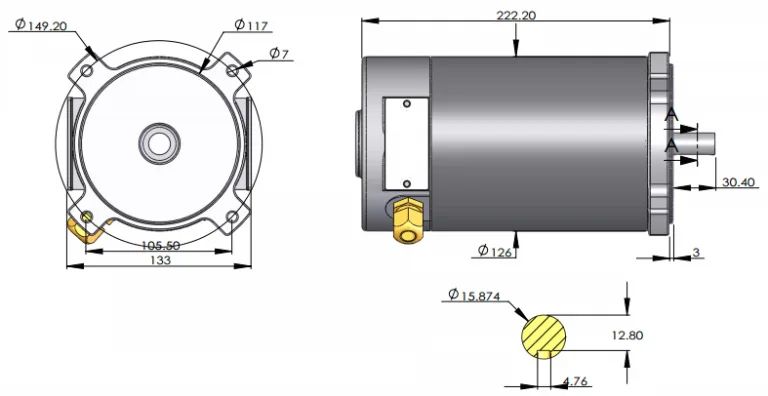

Detailed Images

Brushed motor list

| Sort | Voltage | Speed | Output | Load | Torque |

| (V) | (RPM) | (W) | (A) | (Nm) | |

| DC0.37/12-126 | 12 | 1700 | 370 | 35 | 2.07 |

| DC0.54/12-126 | 12 | 1500 | 540 | 55 | 3.3 |

| DC0.375/12-126 | 12 | 1200 | 375 | 39 | 2.98 |

| DC0.75/24-126 | 24 | 3500 | 750 | 38 | 2.04 |

| DC0.54/24-126 | 24 | 2500 | 540 | 29 | 1.98 |

| DC0.54B/24-126 | 24 | 2000 | 540 | 29 | 2.8 |

| DC0.37/24-126 | 24 | 1700 | 370 | 19 | 2.07 |

| DC0.54C/24-126 | 24 | 1500 | 540 | 31 | 3.43 |

| DC0.4/24-126 | 24 | 1200 | 400 | 21 | 3.18 |

| DC0.37/27-126 | 27 | 1500 | 370 | 16 | 2.35 |

| DC0.37/29-126 | 29 | 1100 | 370 | 15 | 3.21 |

| DC0.375/42-126 | 42 | 1400 | 375 | 11 | 2.55 |

| DC0.54/48-126 | 48 | 2000 | 540 | 14 | 2.8 |

| DC0.54B/48-126 | 48 | 1700 | 540 | 13 | 3.03 |

| DC0.375/48-126 | 48 | 1500 | 375 | 9 | 2.38 |

| DC0.54/60-126 | 60 | 1800 | 540 | 11 | 2.86 |

| DC0.54B/60-126 | 60 | 1500 | 540 | 9 | 3.43 |

| DC0.54/74-126 | 74 | 1700 | 540 | 9 | 3.03 |

| DC0.5/90–126 | 90 | 1600 | 500 | 6 | 2.98 |

| DC0.375/90-126 | 90 | 1750 | 375 | 5 | 2.04 |

| DC0.54/90-126 | 90 | 1700 | 540 | 7 | 3.03 |

| DC0.375/110-126 | 110 | 3200 | 375 | 10 | 1.11 |

| DC0.375B/110-126 | 110 | 1750 | 375 | 4 | 2.04 |

| DC0.54/110-126 | 110 | 1700 | 540 | 6 | 3.03 |

| DC0.375C/110-126 | 110 | 1500 | 375 | 4 | 2.38 |

| DC0.54/150-126 | 150 | 3200 | 540 | 4 | 1.61 |

| DC0.54/180-126 | 180 | 2200 | 540 | 4 | 2.34 |

| DC0.54B/180-126 | 180 | 2000 | 540 | 4 | 2.57 |

| DC0.375/180-126 | 180 | 1700 | 375 | 2.8 | 2.1 |

| DC0.54C/180-126 | 180 | 1500 | 540 | 4 | 3.43 |

| DC0.375B/180-126 | 180 | 1500 | 375 | 2.8 | 2.38 |

| DC0.375/250-126 | 250 | 1500 | 375 | 2 | 2.38 |

| DC0.54/300-126 | 300 | 1200 | 540 | 2 | 4.29 |

Advantages of Brushed DC motors

- Simple structure

- Easy maintenance

- Relatively simple manufacturing process

- Low cost.

- Simple control, suitable for applications where high precision is not required.

- High starting torque, suitable for equipment that requires instant starting and large loads, such as power tools and small lifting equipment.

- Wide range of applications, suitable for low-voltage and low-power applications.

Customized Motors

For custom built DC motors, please contact our team. To prepare an accurate quotation, kindly provide the following details:

- Brushed or Brushless Customer preference

- Output power (W) Horsepower/watts/torque rated at full load speed

- Voltage (V) i.e 12v DC …….. 220v AC

- Motor speed (RPM) Revolutions per minute of the shaft at full load Voltage

- Application e.g. traction, airconditioning, etc.

- Duty Most motors are rated continuous. Some applications however may use motors designed for intermittent duty

- Configuration/Frame Our products are according to IEC standard, we also can customize the flange and shaft according to the customer drawing

- Controller function e.g. forward/reverse, variable speed, acceleration profile, etc.