Product Specifications

| Brand Name: | Volcano Electric | Model Number: | BLDC1.1-100 | Type: | Brushless DC Motor |

| Output Power: | 1.1KW | DC Voltage: | 72V DC, 220V AC, 380V AC | Speed Range: | 2900 RPM |

| Controller: | Customized, Optional | Braker: | Optional | Insulation Class: | Class B/F/H |

| Enclosure: | IP44 / IP54 | Poles: | 4P, 6P, 8P… | Wire: | 100% copper |

| Housing: | Aluminum | Efficiency: | IE3.0 , IE 4.0 | ||

| Duty: | S1 (continuous) | Place of Origin: | Zhejiang, China (Mainland) | Standard: | IEC / NEMA standard |

| Application: | variable speed pumps, constant pressure pumps | ||||

At what applications you need Brushless DC motors replace conventional wound AC motors.

Any one of the below requirements.

- Variable speed application

- Require High Start Torque

- Low /High speed application

- Minimize Motor size demands

- Customized Speed, work at any defined speed, ( the rated speed of AC motor is limited, 2 poles-3000RPM, 4 poles -1500RPM @50HZ, 2 poles-3600RPM, 4 poles -1800RPM @60HZ)

Product Description

Smart pump systems are revolutionizing how water is being used—not just satisfying your requirements, but adding real value with integrated intelligence that easily adapts to changing needs.

For today, the majority of constant-pressure pump installations are based on “VFD (Variable Frequency Drive + AC motor)” design. AC motors lose efficiency when run at a speed higher than they are rated for, a common occurrence in the water supply industry.

BLDC motors have high full and part load efficiencies across a wide speed range unlike the AC motors, thus could be a real game changer for pump systems.

Let’s say we take our 1.1kw, 2900RPM BLDC motor for a centrifugal pump. Engineered to replace equal power AC motors, it’s offered in 72VDC, 220VAC and 380VAC versions to suit a variety of systems. Its high efficiency (even at different speeds) cuts energy bills, and it’s virtually maintenance-free — it saves time and money on maintenance, too.

As time passes, the user will appreciate both the energy savings and zero maintenance requirement of this BLDC motor + controller package and realize that it is the more cost-effective option, compared to the VFD + AC motor route.

Various Constant Pressure Pump Systems

| VFD + AC Motor | Controller + PM Motor | ||

| Advantages | Intelligent pump systems that improve theway you use water and provide added value,accommodate a wide range of flowdemand, allowing to use the water they need, when they need it. | ||

| VFD/Controller Efficiency | 95%-98% The signal is not sinesoid,weaken the motor efficiency |

>98% | |

| Motor Efficiency | Rated Speed | 70%-85% | >88% |

| Variable speed | reduce sharply | Maintain at high level, over 80% | |

| Example P=750W | 75-85% @ Rated Speed lower than 70% @500RPM |

over 88% @ Rated Speed Maintain at 80% @500RPM |

|

| Start Torque | Low | High | |

| High Speed Ability | 2 poles-3000 RPM 4 poles-1500RPM @50HZ |

10,000+ RPM | |

| Cost | – | a little higher | |

| Install | IEC/NEMA/Customized ,substitute for each, noneed to rebuild the pump structure | ||

| *The PM motor is able to control at lowspeed with high efficiency. The PM motor system has high efficiency |

|||

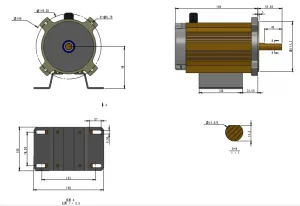

1.1KW 2900RPM Centrifugal Pump motor is one of our brushless DC motor motors used in centrifugal pumps. Which replace the same power AC motors. The efficiency is much higher though the initial cost is a little higher. But for long terms, the energy saving of Brushless DC motors and free maintenance, the benefits you get will obviously considerable.

Detailed Images

Advantages of Brushless DC motors

- Less maintenance and longer service life

- Less noise

- Higher power to weight ratio

- More energy efficiency( generally above 90%, is high efficiency under wide speed variation even high speed changes)

- Less temperature rise-better heat dissipation because of absence of winding construction

- Reduction of EMI

- Flexible Voltage selections- 72VDC, 220VAC, 380VAC for different installations

Customized Motors

For customized Motors, please contact our technician, Ordinary, we have to know the following information to get a professional proposal:

- Brushed or Brushless: Customer preference

- Output power (W): Horsepower/watts/torque rated at full load speed

- Voltage (V): i.e 12V DC …….. 450V AC

- Motor speed (RPM): Revolutions per minute of the shaft at full load Voltage

- Application: e.g. traction, air condition, etc.

- Duty: Most motors are rated continuous. Some applications however may use motors designed for intermittent duty

- Configuration/Frame: Our products are according to IEC standard, we also can customize the flange and shaft according to the customer drawing

- Controller function: e.g. forward/reverse, variable speed, acceleration profile, etc.