Product Description

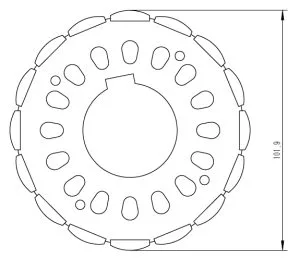

The motor rotor is the core rotating component for electric motors and generators to achieve electromechanical energy conversion. Its core function is to generate rotational torque or induced voltage through interaction with the stator magnetic field (electromagnetic induction or permanent magnetic force), which directly determines key performance indicators of the motor such as efficiency, torque, rotational speed, vibration and noise, and reliability.Different types of motors have different rotor structures, but they are basically composed of an iron core, a conductive system (windings or conductors), a rotor shaft, and auxiliary components. All components work together to ensure energy conversion efficiency and mechanical reliability.

Permanent magnet rotor: It uses permanent magnetic materials such as neodymium-iron-boron and samarium-cobalt, and is installed through methods such as surface-mounted, internal-mounted (V-shaped or U-shaped arrangement) or Halbach array. It has the advantages of high efficiency and high power density, and is widely used in scenarios such as new energy vehicle drive motors and servo motors. Internal-mounted permanent magnet rotors can improve reluctance torque through magnetic circuit design and enhance motor performance.

We mainly focus on the design and production of Bonded Neodymium Magnet Rotors, Ferrite Magnet Rotors, Halbach Magnet Rotors, and Neodymium Arc Magnet Rotors.

Feel free to contact our team at info@volcanomotor.com for any technical support.

Detailed Images

For customized DC Motors, please contact our technician. Ordinary, we have to know the following information to get a professional proposal:

- Brushed or Brushless Customer preference

- Output power (W) Horsepower/watts/torque rated at full load speed

- Voltage (V) i.e 12v DC …….. 450v AC

- Motor speed (RPM) Revolutions per minute of the shaft at full load Voltage

- Application e.g. traction, airconditioning, etc.

- Duty Most motors are rated continuous. Some applications however may use motors designed for intermittent duty

- Configuration/Frame Our products are according to IEC standard, we also can customize the flange and shaft according to the customer drawing

- Controller function e.g. forward/reverse, variable speed, acceleration profile, etc.