Product Specifications

| Brand Name: | Volcano Electric | Model Number: | VOL-BL75B38 | Type: | Brushless DC Motor |

| Output Power: | 750W | DC Voltage: | 380Vac | Speed Range: | 850 RPM |

| Controller: | Customized, Optional | Braker: | none | Insulation Class: | Class F |

| Enclosure: | IP65 | Poles: | 12P | Wire: | 100% Copper Coil |

| Current: | 4A | Sensor: | none | Certification: | 3C, CE, UL |

| Housing: | Aluminum frame | Efficiency: | 88% | ||

| Duty: | S1, customized | Place of Origin: | Zhejiang, China (Mainland) | Standard: | EC motor |

| Application: | fan, ventilation | ||||

Product Description

EC motors are often referred to as brushless DC motors because they eliminate the need for brushes and a commutator found in traditional brushed DC motors. The absence of these components reduces friction, minimizes maintenance requirements, and enhances overall reliability.The heart of EC motors lies in their electronic commutation system. Integrated sensors detect the rotor position, allowing the control electronics to precisely manage the timing of current switching.

EC motors are renowned for their energy-saving capabilities. The precise control of the motor speed and the elimination of energy losses associated with brush friction contribute to significant energy efficiency improvements.

Photovoltaic

The high-voltage motor can be paired with solar panels and batteries using a dedicated high-voltage solar energizer, enabling solar, battery, and grid electricity to mutually support and provide uninterrupted power to multiple motors.

This system creates a highly efficient conversion unit that maximizes the use of solar energy while greatly lowering electricity expenses.

We insist that quality and honesty come first. Waiting for you and feel free to contact our team at info@volcanomotors.com for any technical support.

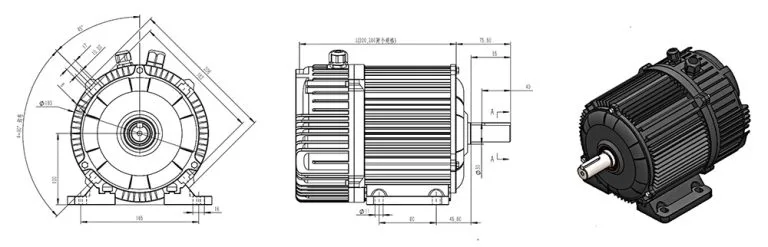

Motor construction

Brushless motor also have the stator and rotor same like the common dc motor, but it cancel the brushes. The stator used by silicon steel sheet and the rotor make by permanent magnet. It can be 2 poles to 16 poles just as you wish. Different with the brushes dc motor, the commutation of the BLDC motor is electronically controlled.

Configuration

Brushless motor list

| Motor type | Output | Voltage | Load | Speed | Rated Torque | Poles | Efficiency | Noise |

| KW | V | A | RPM | N.m | % | dB | ||

| VOL-BL220C38 | 2.2 | 380 | 11 | 750 | 28 | 12 | 91 | 60 |

| VOL-BL150B38 | 1.5 | 380 | 8 | 700 | 20.46 | 12 | 90 | 62 |

| VOL-BL150C38 | 1.5 | 380 | 8 | 1000 | 14.33 | 12 | 90 | 60 |

| VOL-BL75B38 | 0.75 | 380 | 4 | 850 | 8.43 | 12 | 88 | 60 |

| VOL-BL75C38 | 0.75 | 380 | 4 | 1500 | 4.78 | 12 | 88 | 62 |

| VOL-BL150C22 | 1.5 | 220 | 12 | 450 | 31.83 | 10 | 87 | 60 |

Advantages of Brushless DC motors

- Lower Maintainance and longer lifetime – no brush and commutator erosion

- Lower electromagnetic noise -the elimination of brush contact

- Higher power to weight ratio

- Higher efficiency ( in general higher than 90%)

- Lower temperature rise – more efficient heat dissipation due to winding construction

- Simple structure

- Higher speed range- no limit of brushes and commutator

Customized Motors

For customized Motors, please contact our technician, Ordinary, we have to know the following information to get a professional proposal:

- Brushed or Brushless: Customer preference

- Output power (W): Horsepower/watts/torque rated at full load speed

- Voltage (V): i.e 12V DC …….. 450V AC

- Motor speed (RPM): Revolutions per minute of the shaft at full load Voltage

- Application: e.g. traction, air condition, etc.

- Duty: Most motors are rated continuous. Some applications however may use motors designed for intermittent duty

- Configuration/Frame: Our products are according to IEC standard, we also can customize the flange and shaft according to the customer drawing

- Controller function: e.g. forward/reverse, variable speed, acceleration profile, etc.

Application:

EC (Electronically Commutated) motors, also known as brushless DC motors, have gained popularity due to their energy efficiency, reliability, and controllability. These motors find applications in various industries and systems. Here are some common applications of EC motors:

- HVAC Systems: EC motors are widely used in heating, ventilation, and air conditioning (HVAC) systems for applications such as fans and pumps. They offer variable speed control, which helps optimize energy consumption based on the actual cooling or heating demand.

- Refrigeration: EC motors are employed in refrigeration systems, including refrigerators and freezers. Their efficiency and ability to operate at variable speeds make them suitable for maintaining precise temperature control.

- Appliances: EC motors are found in household appliances such as washing machines, dryers, and dishwashers. Their energy efficiency helps reduce overall power consumption and operating costs.

- Industrial Automation: EC motors are used in various industrial automation applications, including conveyor systems, robotics, and material handling equipment. Their precise control and high efficiency contribute to improved overall system performance.

- Pumps and Compressors: EC motors are employed in pumps and compressors across different industries. Their ability to provide variable speed control ensures that these systems can adapt to changing operational requirements, enhancing energy efficiency.

- Automotive: EC motors are increasingly used in the automotive industry for applications such as cooling fans, power steering systems, and electric powertrains in electric vehicles (EVs). Their efficiency and compact design make them suitable for these applications.

- Agricultural Equipment: EC motors are utilized in agricultural machinery, such as crop sprayers and ventilation systems in greenhouses. Their controllability allows for precise adjustment based on specific requirements.

- Medical Equipment: EC motors find applications in various medical devices and equipment, including pumps for fluid control and ventilation systems in healthcare facilities. Their reliability and precise control are critical in these sensitive environments.

- Computer Cooling: EC motors are used in computer fans and cooling systems. Their efficiency and variable speed control help maintain optimal operating temperatures for electronic components.

- Commercial Refrigeration: EC motors are employed in commercial refrigeration systems, such as display cases in supermarkets and walk-in coolers. Their ability to modulate speed based on cooling demand contributes to energy savings.

The versatility, energy efficiency, and controllability of EC motors make them suitable for a wide range of applications across different industries. As technology continues to advance, the adoption of EC motors is likely to increase further, contributing to energy savings and improved performance in various