A BLDC Motor plays a critical role in modern industrial settings. These motors offer significant advantages over traditional counterparts, including energy efficiency, often saving 20% or more, and extended operational lifespans exceeding 10,000 hours. This superior performance, along with precision control capabilities, makes them indispensable for many applications. Selecting what are the best BLDC motors for industrial automation therefore requires a meticulous process. A high speed BLDC motor, for instance, demands specific considerations for optimal integration. Understanding how to extend the lifespan of industrial BLDC motors also guides choices for long-term reliability. A reputable BLDC motor manufacturer China can provide robust solutions.

Key Takeaways

- Understand your motor’s job. Match the motor’s power and speed to the work it needs to do. This helps it work well and last longer.

- Check the motor’s surroundings. High heat and moisture can hurt the motor. Pick a motor with the right protection for its environment.

- Think about how much the motor costs over time. BLDC motors save money on electricity and repairs. They are a good choice for long-term use.

- Choose the right control system. Some motors use sensors for exact control. Others work without sensors for simpler setups. Pick what fits your needs.

Defining Application Requirements for Your BLDC Motor

Choosing the right motor begins with a clear understanding of its intended job. Industrial environments present diverse challenges. Therefore, defining the application’s specific requirements is the first critical step. This process ensures the selected motor performs reliably and efficiently.

Analyzing Load Type and Characteristics for BLDC Motor Selection

The type of load a motor drives directly impacts its performance and lifespan. Industrial applications feature many different load types. These include motion control systems, linear actuators, servomotors, and actuators for industrial robots. Other common uses are extruder drive motors, feed drives for CNC machine tools, pump drives, fan drives, and spindle drives. Industrial positioning and actuation applications, assembly robots, and linear motors also represent typical loads.

Understanding the load’s characteristics is crucial. Engineers must compare the motor’s torque-speed curve features with the task’s demands. For example, conveyor belts or elevators need significant initial force. These applications benefit from motors with strong starting torque. Motors with steep pull-out torque curves are ideal for rapid starts. Those with flatter curves work better for consistent operations. This careful selection, guided by the torque-speed curve, improves performance. It also prevents problems like stalling or overheating.

Consider these key torque characteristics:

| Characteristic | Description |

|---|---|

| Pull-Out Torque | This is the maximum torque a motor can produce while keeping a constant speed. It shows the motor’s ability to operate steadily under load. Winding design, magnetic circuits, and control strategy all affect it. This torque is vital for handling tough loads. |

| Continuous Torque | This is the maximum torque a motor can maintain forever without getting too hot. It is important for applications needing constant output, like conveyor systems or pumps. |

| Peak Torque | This is the maximum torque a motor can produce for a short time. It is essential for applications needing high torque during acceleration or short tasks, such as robotic arms or cutting tools. |

| Torque-Speed Curve | This shows how torque and speed relate. BLDC motors typically offer high torque at low speeds. This makes them good for applications needing high starting torque. As speed goes up, torque usually goes down. Understanding this curve helps select a motor that delivers the necessary torque within the desired speed range. |

Incorrectly matching a motor’s torque-speed characteristics to a load can cause issues. The motor may not deliver enough torque at the needed speed, leading to underperformance. An oversized motor operating below its best point will also be inefficient.

Determining Operating Mode and Duty Cycle for BLDC Motor Performance

The way a motor operates over time is its operating mode. This includes continuous operation or intermittent use. The duty cycle describes the proportion of time a motor is active versus idle. It is a critical factor for motor performance and longevity.

Pulse Width Modulation (PWM) control regulates the power supplied to a BLDC Motor. It adjusts the duty cycle. The duty cycle is the ratio of ‘on’ time to the total pulse period. A higher duty cycle delivers more voltage, which increases motor speed. This method is important for motors because it ensures accurate speed control. It also minimizes power losses and reduces heat generation. This improves the motor’s lifespan by preventing too much wear and tear. It also allows the motor to operate at cooler temperatures.

Proper duty cycle management is essential for motor durability. Avoiding continuous operation under high load conditions helps reduce heat buildup. Selecting a motor with the correct power capacity prevents overloading and excessive heating. Environmental factors also play a role. Ensuring good ventilation and avoiding high-temperature environments are crucial for safe operating conditions.

Identifying Precision Control Needs for Your BLDC Motor

Many industrial applications demand very precise control. This includes accurate motor control for coordinated, repeatable motion in industrial robots. Closed-loop control is essential for accuracy and repeatability in demanding environments. These include robotics, CNC machinery, servo-driven systems, and high-end automation.

Specific precision control requirements often include:

- Precise speed control

- Precise torque control

- Position control, especially for robotics and CNC machines

These precise controls ensure machines perform tasks with high accuracy and consistency. This leads to better product quality and operational efficiency.

Selecting Core Specifications for an Industrial BLDC Motor

Choosing the right industrial motor involves looking closely at its core specifications. These details ensure the motor performs its job well and lasts a long time. Engineers must match the motor’s capabilities to the application’s demands.

Power and Torque Selection for Your BLDC Motor

Power and torque are fundamental to motor selection. They directly affect how well a system works and its overall cost. Engineers calculate output power by multiplying speed (in radians per second) by torque (in Newton-meters). For best efficiency and long life, motors should run close to their peak efficiency point. This often means using less than 30% of their stall torque for continuous tasks. Operating a motor beyond 60% of its peak torque capacity enters a ‘Danger Zone.’ This can cause overheating, damage to windings, and a shorter lifespan. Such issues increase system costs due to early failures or the need for larger motors to handle occasional heavy loads. Gearboxes can boost torque, but their own efficiency must be part of the overall calculation.

Selecting the correct power and torque is vital for equipment operation. It directly influences efficiency and cost. Key considerations include:

- Load Type: Constant loads allow for motors that match their rated power and torque. Variable loads need motors with a wider speed range.

- Operating Mode: Continuous operation requires stable speed and torque. Intermittent operation focuses on starting and braking performance.

- Torque Requirements: Motors must meet starting torque and maximum load torque needs. They also need extra instantaneous torque for acceleration, deceleration, or sudden load increases.

- Speed (RPM): Applications dictate speed, from high-speed fans to low-speed, high-torque electric vehicles.

- Voltage and Current: Matching these to load requirements prevents overheating from too much current. It also prevents insufficient torque from low current. Both issues affect efficiency and motor lifespan.

Speed Range and Control for Optimal BLDC Motor Operation

Industrial applications often require precise speed control. Engineers control BLDC motor speed by changing the voltage supplied to it. This is similar to how brushed DC motors work. Pulse-Width Modulation (PWM) from a microcontroller often achieves this. A low mark-space ratio in the PWM signal means a low average voltage goes to the stator coils. This makes the motor turn slowly. As the voltage increases, the rotor speed also increases. A speed control algorithm, like PID, can keep the motor from slowing down under load.

Several methods control motor speed:

- PWM (Pulse Width Modulation) Control: This common method adjusts the duty cycle of the PWM signal. This changes the average voltage to the motor, regulating its speed.

- Voltage Control Method: Varying the input voltage controls motor speed. More voltage increases speed, less voltage slows it down.

- Closed-Loop Control Using Feedback: This method uses feedback from Hall effect sensors or encoders. It monitors and adjusts motor speed in real-time. This ensures precise and stable regulation.

- Sensorless Control Using Back EMF: This method does not need Hall sensors. It uses the back electromotive force (EMF) from the windings to estimate rotor position and speed.

- PID Control for Precise Speed Regulation: Proportional-Integral-Derivative (PID) control is widely used. It maintains the desired motor speed by dynamically adjusting control parameters.

Voltage and Current Matching for Your BLDC Motor System

Properly matching voltage and current is crucial for a motor system’s health. Operating a motor significantly above its rated voltage can damage insulation. It can also demagnetize magnets. Running it below the rated voltage leads to poor performance. The motor may not reach its intended speed. An undersized driver can experience overcurrent and fail. This often happens during motor startup or when loads suddenly increase. An undersized motor will overheat and burn out.

Mismatched voltage and current can lead to several problems:

- System failure due to insufficient torque or speed.

- Overheating and burnout of an undersized motor.

- Damage to insulation and demagnetization of magnets from excessively high voltage.

- Poor performance and inability to reach rated speed from excessively low voltage.

- Driver failure during motor startup or load spikes if undersized.

Considering Environmental Factors for BLDC Motor Durability

Industrial environments present unique challenges for motor operation. Environmental factors significantly impact a motor’s lifespan and performance. Engineers must carefully consider these conditions when selecting a BLDC Motor.

Operating Temperature and Humidity for BLDC Motor Longevity

Temperature and humidity directly affect motor longevity. High temperatures degrade motor components. For example, a 10℃ reduction in workshop temperature can extend a motor’s lifespan by 28%. Temperatures above 45℃ above ambient on the housing indicate danger. Insulation life halves with every 10℃ rise. Winding temperature rising from 80℃ to 100℃ drastically reduces bearing grease lifespan from 9,000 hours to 2,300 hours.

Extreme temperatures also affect motor performance and material degradation:

| Parameter | Initial Value (25°C) | Final Value (125°C) |

|---|---|---|

| Terminal Resistance (Rmt) | 0.59Ω | 0.83Ω |

| Torque/Voltage Constant (K) | 0.071 V/(rad/s) or Nm/A | 0.057 V/(rad/s) or Nm/A |

| Locked Rotor Current (ILR) | N/A | 28.92A |

| Locked Rotor Torque (TLR) | N/A | 1.65Nm |

| No Load Speed (n0) | N/A | 3979 RPM |

| Motor Regulation (Rm) | N/A | 2412 RPM / Nm |

As motor temperature increases, winding resistance increases. This leads to more heat generation. The magnetic flux density of permanent magnets decreases with increasing temperature. This reduces flux density. If the maximum temperature rating is exceeded, partial demagnetization can occur. This permanently alters performance.

Humidity also poses a threat. Workshops with over 80% humidity can reduce motor lifespan by 40%. Using food desiccant in junction boxes helps combat moisture.

Required IP Rating and Enclosure for BLDC Motor Protection

The Ingress Protection (IP) rating indicates a motor’s resistance to dust and water. This rating is crucial for industrial environments. IP65 waterproof motors are highly reliable for applications needing protection against dust and water jets. They feature a completely sealed housing. IP67 waterproof motors offer complete dust protection. They also protect against immersion in water up to 1 meter deep for up to 30 minutes.

Specific industries require different IP ratings:

- Manufacturing plants often need an IP54 or higher rating.

- The food and beverage industry typically requires an IP66 or higher rating for washdowns.

- Chemical processing plants usually necessitate an IP65 or higher rating.

Noise and Vibration Considerations for BLDC Motor Integration

Motors generate noise and vibration. These factors can affect equipment and worker comfort. Engineers can mitigate noise through several techniques:

- Electromagnetic Noise Reduction:

- Utilize low-EMI drivers.

- Optimize PWM switching frequency (above 20 kHz).

- Employ shielded cables and proper PCB grounding.

- Mechanical Noise Reduction:

- Use precision bearings.

- Perform dynamic rotor balancing.

- Ensure proper shaft alignment.

- Magnetic Noise Reduction:

- Implement skewed stator slots.

- Use distributed windings.

- Optimize pole-slot combinations.

- Structural Resonance Noise Reduction:

- Employ vibration dampers and isolators.

- Reinforce motor housing for structural stiffening.

Evaluating Efficiency and Control Systems for Your BLDC Motor

Choosing an industrial motor also involves a close look at its efficiency and control systems. These aspects directly impact operational costs and performance. Understanding these elements helps engineers make informed decisions.

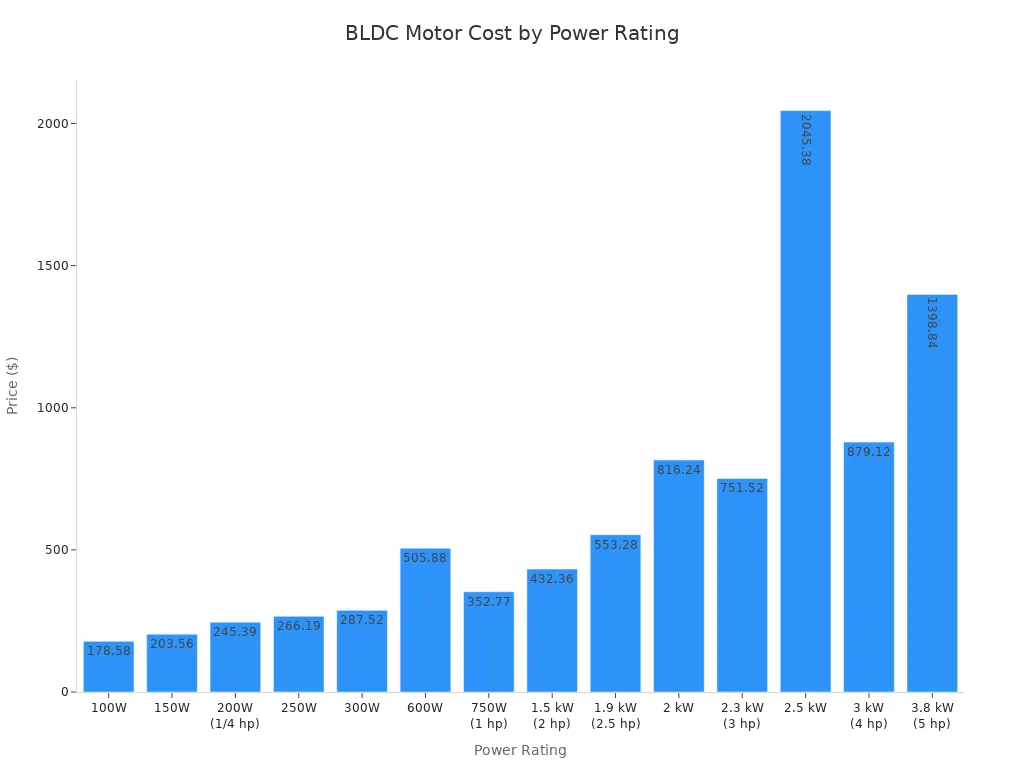

Energy Consumption and Long-Term Costs of a BLDC Motor

Industrial BLDC motors offer significant energy efficiency compared to induction motors. Their design uses permanent magnets on the rotor. This eliminates secondary copper losses common in induction motors. Induction motors need more electrical power to create magnetic flux in both the stator and rotor, leading to higher losses. BLDC motors do not induce current in the rotor, avoiding these losses. This design makes BLDC motors more efficient, especially at lower speeds and torques. They also perform better over a wider operating range than variable-speed induction motors. For example, a conveyor belt running at a constant speed can use 37% less electricity annually with a brushless DC motor.

BLDC motors contribute to long-term operational cost savings. They eliminate brushes and commutators. This reduces energy loss from friction and significantly decreases heat production. The lack of physical contact between moving and stationary parts minimizes electrical arcing and mechanical wear. This leads to longer equipment life and less maintenance downtime. Their ability to maintain high efficiency even at lower loads and precisely control power output further reduces wasted energy. This translates directly to lower electricity costs and quicker payback periods for the initial investment.

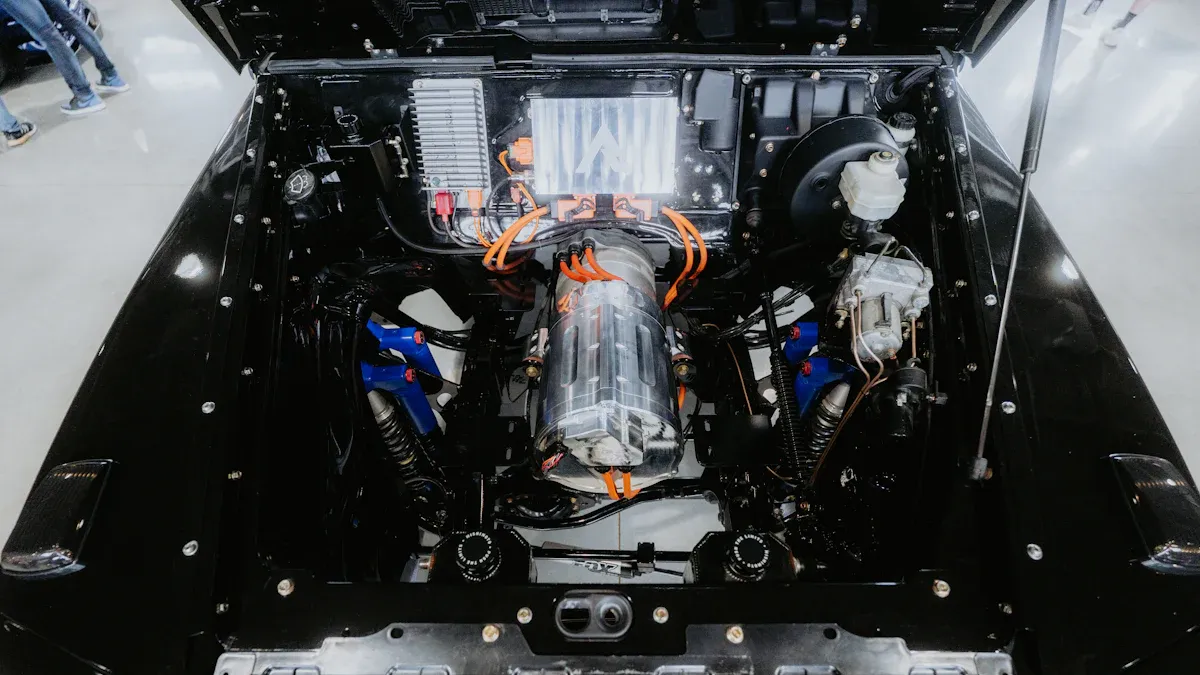

Consider the annual cost differences:

| Cost Factor | Brushless Motor | Brushed Motor | Annual Difference |

|---|---|---|---|

| Energy consumption | $2,400 | $3,000 | $600 savings |

| Maintenance labor | $200 | $800 | $600 savings |

| Replacement parts | $50 | $300 | $250 savings |

| Downtime costs | $400 | $1,600 | $1,200 savings |

| Total Annual Costs | $3,050 | $5,700 | $2,650 savings |

The payback period for brushless motor systems in high-utilization applications typically ranges from 12-18 months. This shows clear financial advantages for brushless technology in applications with annual operating costs exceeding $3,000.

Sensored vs. Sensorless Control for BLDC Motor Applications

Choosing between sensored and sensorless control impacts motor performance. Each method has distinct advantages and disadvantages.

Sensored BLDC motors use Hall sensors or encoders to detect rotor position.

- Advantages: They offer precise speed and torque control. They also provide smooth operation at low speeds and reliable starting.

- Disadvantages: They cost more due to the sensors. They also require more wiring and a more complex control strategy. Sensors introduce additional potential failure points.

Sensorless BLDC motors estimate rotor position using back-EMF.

- Advantages: They have a simpler motor design without extra sensors. They are generally cheaper and offer higher reliability due to fewer components.

- Disadvantages: They can struggle with low-speed operation or starting without direct feedback. Their control algorithms are often more complex.

| Feature | Sensored BLDC Motor | Sensorless BLDC Motor |

|---|---|---|

| Rotor Position Detection | Hall sensors or encoders | Back-EMF estimation |

| Startup Performance | Excellent, immediate torque | Weak, delayed torque |

| Low-Speed Control | Smooth and precise | Less stable |

| High-Speed Efficiency | Good | Excellent |

| Cost | Higher | Lower |

| Durability | Moderate | High |

| Maintenance | Requires care for sensors | Minimal |

| Environmental Suitability | Sensitive to interference | Robust and sealed |

| Complexity of Control | Simpler electronics | Advanced algorithms required |

| Ideal Application | Precision control and frequent stops | Continuous motion and cost-sensitive AGVs |

Driver and Controller Compatibility for Your BLDC Motor

Properly matching the driver and controller to the motor is essential. The Electronic Speed Controller (ESC) must align with the motor’s voltage and current needs. Controllers should offer fine-tuned control over speed and torque. The control system must integrate seamlessly with existing hardware and software.

BLDC motors require a motor controller for electronic commutation. Drivers come in internal (small, integrated) and external (more common, dedicated units) types. All drivers operate over a range of input/output voltages and input currents. Defining power requirements is crucial. This includes voltage (e.g., 12VDC, 24VDC) and current. BLDC motors have higher current ratings. Maximum current draw limits are critical, especially for battery-powered devices. Consider both input power (Current * Voltage) and output power (Speed * Torque). Datasheets often show output power.

Other considerations include motor compatibility (matching voltage, current, pole pairs, encoder use), control method (sensored vs. sensorless, FOC), and power/performance (rated power, max power, speed control, current ratings). Advanced features, efficiency, noise levels, cost, and ease of integration also play a role.

Addressing Practical Constraints in BLDC Motor Selection

Engineers must consider practical limitations when selecting motors for industrial applications. These constraints often include physical space, budget, and long-term maintenance needs. Addressing these factors ensures successful integration and operation.

Size and Weight Limitations for Your BLDC Motor

Industrial machinery often has limited space. Therefore, engineers must consider available space and weight limitations. For compact designs, flat motors are suitable. Their outer diameters range from approximately 43 to 90 millimeters. These motors typically weigh between 57 and 600 grams. Motors with integrated controllers save space. They combine the motor and controller into a single unit. This reduces the overall system footprint. For lightweight and compact solutions, coreless or slotless motors are often preferred.

Motors possess high power density. This means they deliver significant power within restricted size and weight parameters. Internal drivers are small and integrate directly into the motor. They are a logical choice for applications needing basic motor function. This demonstrates how size influences component selection. Oversized motors lead to wasted energy, space, and increased costs. This highlights the importance of size and weight considerations for efficiency and cost-effectiveness.

Cost-Effectiveness and Budget for Industrial BLDC Motors

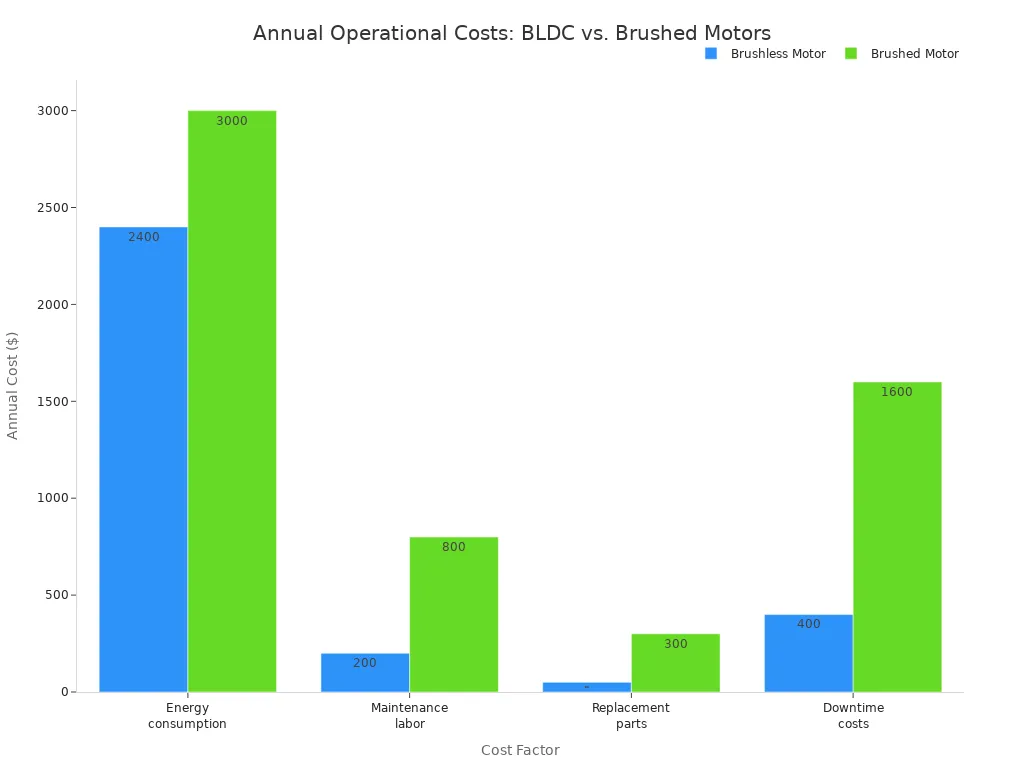

The initial purchase price of motors varies significantly.

| Power Rating | Price Range |

|---|---|

| 100W | $178.58 |

| 150W | $203.56 |

| 200W (1/4 hp) | $245.39 |

| 250W | $266.19 |

| 300W | $287.52 |

| 600W | $505.88 |

| 750W (1 hp) | $352.77 |

| 1000W (1 kW) | $415.85 – $880.42 |

| 1.5 kW (2 hp) | $432.36 |

| 1.9 kW (2.5 hp) | $553.28 |

| 2 kW | $816.24 |

| 2.3 kW (3 hp) | $751.52 |

| 2.5 kW | $2,045.38 |

| 3 kW (4 hp) | $879.12 |

| 3.8 kW (5 hp) | $1,398.84 |

Motors generally have a higher initial purchase price compared to traditional motors. This is due to their complex integrated drive electronics and advanced components. However, engineers must consider the total cost of ownership (TCO). TCO includes purchase price, energy consumption, maintenance, and lifespan. Motors are highly energy-efficient. This leads to substantial energy savings over time. They also require minimal maintenance. This reduces labor and replacement costs. Motors typically have a longer lifespan. This reduces the frequency of replacements.

| Motor Type | Initial Manufacturing Cost | Maintenance Cost (3-year period) | Total Cost of Ownership |

|---|---|---|---|

| Brushed Motor | $15-25 | $20-30 (brush replacements) | $35-55 |

| Brushless Motor | $35-50 | $5-10 (rare maintenance) | $40-60 |

Over a 20,000-hour operational period, a brushless motor could be more than ten times cheaper than a brushed motor. This is due to reduced maintenance and replacement needs.

Maintenance and Serviceability of Your Chosen Motor

All motors require periodic checks and care for optimal performance. Essential maintenance practices include:

- Maintaining detailed logs of inspections, repairs, and test readings.

- Tracking storage dates and implementing a First-In, First-Out (FIFO) system for inventory.

- Storing motors in dry, temperature-stable environments.

- For motors stored between 6 to 12 months, rotating the shaft to prevent lubricant settling.

Common causes of motor failure include overheating, bearing wear, and lubrication issues. Regular inspection is advisable at least once every six months. Key maintenance tips include:

- Inspecting the motor’s exterior: Clean external surfaces and check wires for wear.

- Monitoring motor temperature: Ensure the cooling system functions properly.

- Lubrication and bearing inspection: Listen for unusual noises and lubricate as needed.

Factors contributing to serviceability include:

- Regular Cleaning: Remove dust and debris from the motor housing.

- Wiring Inspection: Check for loose or corroded terminals monthly.

- Parameter Calibration: Optimize driver parameters based on load changes.

- Environmental Adaptation: Avoid prolonged operation in harsh environments.

- Regular Testing: Use professional equipment for early fault detection.

Selecting an industrial motor demands a balance between technical specifications and practical considerations. Engineers must weigh power, speed, and environmental factors against size, cost, and maintenance. A well-chosen BLDC Motor delivers significant long-term benefits. These include superior energy efficiency, enhanced durability, and reduced operational costs. For a robust selection process, follow these steps:

- Thoroughly define application requirements.

- Carefully evaluate core specifications.

- Always consider environmental conditions and practical constraints.

FAQ

What makes BLDC motors ideal for industrial environments?

BLDC motors offer high energy efficiency, often saving 20% or more on power. They also have a long operational lifespan, exceeding 10,000 hours. Their precision control capabilities make them perfect for demanding industrial tasks.

How can one extend the lifespan of an industrial BLDC motor?

Proper selection is key. Match the motor to the load and duty cycle. Manage operating temperature and humidity. Ensure adequate cooling and ventilation. Regular maintenance, like cleaning and lubrication, also helps.

What is the difference between sensored and sensorless BLDC motor control?

Sensored control uses physical sensors to detect rotor position, offering precise low-speed control and reliable starting. Sensorless control estimates rotor position using back-EMF, leading to simpler designs and lower costs, but it can struggle at very low speeds.

Why is the IP rating important for industrial BLDC motors?

The IP (Ingress Protection) rating shows how well a motor resists dust and water. Industrial environments often have dust, moisture, or require washdowns. A suitable IP rating protects the motor from these elements, ensuring durability and reliable operation.